What Materials are Used to Make a Frisbee?

A Frisbee is a beloved toy for many, whether it’s used for casual play or as a competitive sport. But have you ever wondered about the materials that go into making this seemingly simple object? From the outer shell to the inner rim, the disc’s design and composition play a crucial role in its flight patterns and durability. In this article, we’ll take a closer look at the materials used to create a Frisbee, and explore how these components work together to create the perfect throw. So, grip your favorite flying disc and get ready to take off into the world of Frisbee materials!

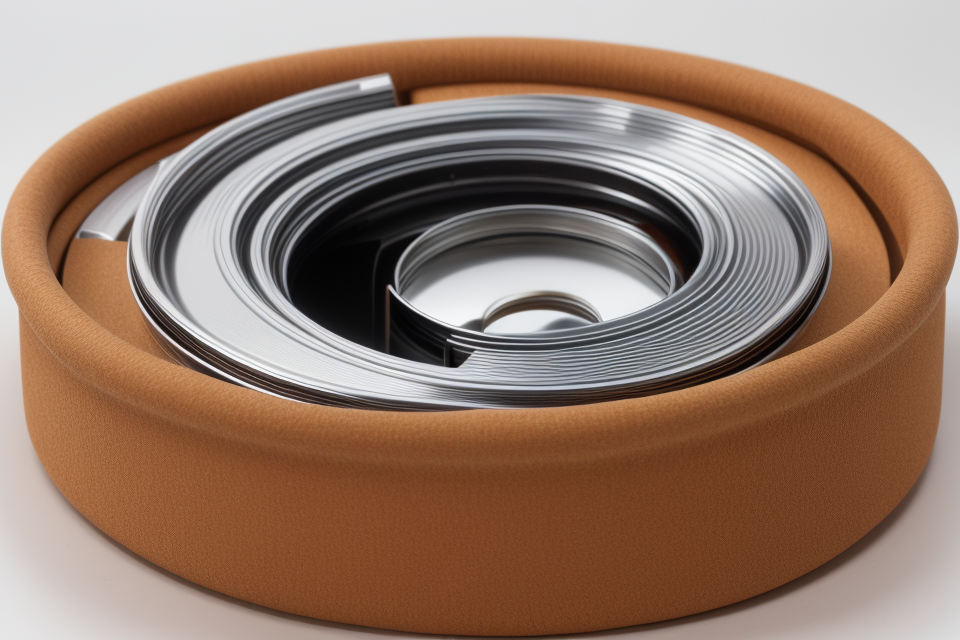

A frisbee is typically made from a plastic material called polyethylene, which is molded into a flat, round disc shape. Some higher-end frisbees may also have a layer of aluminum or titanium added to the rim for increased durability and stability in flight. The design of the frisbee features a slightly curved edge and a small, central “lip” that helps it to fly straight and stable when thrown. The surface of the frisbee may also have a textured or patterned design to help with grip and control during play.

The History of the Frisbee

The First Frisbees

The history of the Frisbee dates back to the 1800s when the first version of the flying disc was invented. The first Frisbees were made of tin and wood, and they were used as pie plates. The name “Frisbie” was stamped on the metal, which later evolved into the modern-day “Frisbee.”

In the early 1900s, the Frisbie brand started manufacturing metal cake pans with a ridged edge that could be used as flying discs. These discs were initially used by college students in the United States as a means of entertainment and as a way to toss and catch food during outdoor picnics.

During World War II, the Frisbie brand stopped producing their flying discs due to metal shortages. However, after the war, the brand resumed production, and the popularity of the Frisbee continued to grow. In the 1950s, the Frisbee gained popularity as a sport, and the first official tournaments were held.

Today, Frisbees are made from a variety of materials, including plastic, foam, and metal. However, the original tin and wood version of the Frisbee remains a symbol of its history and evolution over the years.

The Evolution of the Frisbee

The frisbee, as we know it today, has undergone several changes since its inception. It all started with a plastic disc that was used as a toy by children in the United States. The disc was made from a hard plastic called polyethylene, which was first developed in the 1930s. However, it wasn’t until the 1950s that the frisbee was introduced as a commercial product.

The first frisbees were made by the Wham-O toy company, which is still the most well-known brand of frisbees today. The original frisbee was called the “Flyin’ Saucer,” and it was marketed as a new kind of flying disc that could be thrown and caught.

Over the years, the design of the frisbee has evolved to make it more durable and suitable for various sports. Today, there are several different types of frisbees available, including ultimate frisbee, disc golf, and freestyle frisbee. Each type of frisbee has its own unique characteristics, such as weight, size, and material composition.

One of the most significant changes in the design of the frisbee was the introduction of the “grip” on the edge of the disc. This feature was added to make it easier to throw and catch the frisbee, as well as to prevent it from slipping out of a player’s hand during play.

Another significant development in the history of the frisbee was the introduction of the “flight plate,” which is a raised section on the top of the disc that helps to stabilize the frisbee in flight. This feature has made it possible for players to throw the frisbee with greater accuracy and distance.

Overall, the evolution of the frisbee has been driven by a desire to make it more versatile and suitable for a wider range of sports and activities. Today, the frisbee is enjoyed by people of all ages and skill levels, from casual players to professional athletes.

The Components of a Frisbee

The Plate

The plate is the central component of a frisbee and is made from a specially formulated polypropylene plastic. This material is chosen for its durability, resistance to impact, and ability to withstand the rigors of outdoor play. The plate is typically molded into a symmetrical shape, with a slight rim around the edge to help it fly straighter and further.

One of the key features of the plate is its weight distribution. The majority of the weight is concentrated in the outer rim, which gives the frisbee its stability and allows it to be thrown with precision. The plate is also designed to have a slightly concave surface, which helps to reduce drag and make the frisbee glide more smoothly through the air.

In addition to its structural properties, the plate is also designed to be visually appealing. Many frisbees have bold graphics or designs etched into the surface of the plate, which not only add visual interest but also help to make the frisbee more easily visible to players on the field.

Overall, the plate is a critical component of the frisbee, and its design and construction play a key role in determining the performance and durability of the disc.

The Rim

The rim of a frisbee is an essential component that plays a crucial role in its overall performance. It is the outer edge of the frisbee that is responsible for maintaining its shape and providing stability during flight. The rim is typically made of a durable material that can withstand the rigors of the game and ensure that the frisbee remains in good condition even after being thrown and caught repeatedly.

One of the most common materials used to make the rim of a frisbee is polycarbonate. This material is known for its high strength-to-weight ratio, which makes it ideal for use in sports equipment. Polycarbonate is a type of plastic that is strong, lightweight, and flexible, which makes it perfect for the rim of a frisbee. It can withstand the impact of being thrown and caught, while also remaining lightweight enough to allow the frisbee to fly smoothly through the air.

Another material that is sometimes used to make the rim of a frisbee is aluminum. This material is strong and lightweight, making it a popular choice for sports equipment. Aluminum is also very durable, which means that it can withstand the rigors of regular use. It is also a good conductor of heat, which can help to keep the frisbee at a consistent temperature, even in extreme weather conditions.

In addition to polycarbonate and aluminum, other materials that may be used to make the rim of a frisbee include carbon fiber, titanium, and magnesium. These materials are all known for their strength and durability, which makes them ideal for use in sports equipment. They are also lightweight, which helps to ensure that the frisbee remains easy to throw and catch.

Overall, the rim of a frisbee is a critical component that plays a crucial role in its performance. Whether it is made of polycarbonate, aluminum, carbon fiber, titanium, or magnesium, the rim must be strong, lightweight, and durable to withstand the rigors of regular use. The choice of material for the rim will depend on a variety of factors, including the intended use of the frisbee, the environment in which it will be used, and the preferences of the user.

The Web

The web is one of the most crucial components of a frisbee. It is the part of the frisbee that holds the disc together and gives it its shape. The web is typically made from a strong and flexible material, such as plastic or rubber, and is designed to be lightweight yet durable.

There are different types of webs used in frisbees, each with its own unique properties. For example, some webs are designed to be more rigid, which can help the frisbee fly straighter and further. Other webs are more flexible, which can make the frisbee more responsive to throws and movements.

The web is typically molded onto the disc during the manufacturing process, and is often textured or patterned to provide a secure grip on the frisbee. This is especially important for players who are using the frisbee for sports or competitive play, as they need to be able to grip the disc firmly and throw it accurately.

In addition to providing structure and shape to the frisbee, the web also plays a role in its aerodynamics. The web’s design can affect how the air flows around the disc, which can impact its flight path and distance. Different web designs can also affect the frisbee’s stability in flight, with some webs providing more stability and others allowing for more movement.

Overall, the web is a critical component of the frisbee, providing both structural support and aerodynamic properties. Different web designs can impact the frisbee’s performance, making it an important consideration for players and manufacturers alike.

The Flight Plate

The flight plate is the central component of a frisbee, responsible for its aerodynamic properties and overall performance. It is typically made from a durable plastic material, such as polypropylene or polycarbonate, which provides both strength and flexibility.

One key feature of the flight plate is its rim, which is designed to create a stable airflow around the disc as it is thrown. The rim is typically slightly curved and has a slight edge, which helps to reduce drag and stabilize the flight path of the frisbee.

The flight plate is also usually marked with various colors and designs, which serve as a visual indicator of the frisbee’s weight and flight characteristics. For example, lighter frisbees may have more vibrant colors or patterns, while heavier frisbees may have more subdued designs.

In addition to its aerodynamic properties, the flight plate also plays a role in the frisbee’s durability. It is designed to withstand the impact of catches and throws, as well as the wear and tear of regular use. Many frisbees also have a textured surface, which provides a secure grip on the disc and helps to prevent slips and drops.

Overall, the flight plate is a critical component of a frisbee, responsible for its performance and durability. Its design and materials play a key role in determining the frisbee’s flight characteristics and overall quality.

The Materials Used to Make a Frisbee

Polypropylene

Polypropylene is a widely used plastic material in the manufacturing of frisbees. It is a synthetic polymer that is derived from propylene monomer. Polypropylene is known for its exceptional strength-to-weight ratio, making it an ideal material for use in sports equipment such as frisbees.

One of the key benefits of polypropylene is its resistance to environmental factors such as moisture, chemicals, and extreme temperatures. This makes it an ideal material for outdoor sports equipment that is exposed to various weather conditions.

In addition to its durability, polypropylene is also lightweight, which makes it easy to throw and catch. The material is also flexible, which allows it to bend and flex during flight, providing a stable and predictable flight path for the frisbee.

The manufacturing process of polypropylene involves a series of steps, including polymerization, extrusion, and injection molding. The resulting material is then cut and molded into the desired shape and size of the frisbee.

Overall, polypropylene is a versatile and reliable material that is widely used in the manufacturing of frisbees. Its strength, durability, and lightweight properties make it an ideal choice for this popular outdoor sport.

Polycarbonate

Polycarbonate is a thermoplastic polymer that is widely used in the manufacturing of a variety of products, including frisbees. It is a strong and durable material that is able to withstand the impact and wear and tear that a frisbee is subjected to during play.

One of the key benefits of polycarbonate as a material for frisbees is its ability to maintain its shape and form even when subjected to high levels of stress and pressure. This makes it an ideal material for the manufacturing of frisbees, as it ensures that the frisbee remains stable and consistent in flight, providing a reliable and enjoyable experience for players.

Another advantage of polycarbonate as a material for frisbees is its resistance to moisture and other environmental factors. This means that polycarbonate frisbees are able to withstand exposure to rain, snow, and other forms of wetness, making them suitable for outdoor play in a range of different weather conditions.

In addition to its strength, durability, and resistance to moisture, polycarbonate is also a lightweight material. This makes it an ideal choice for the manufacturing of frisbees, as it allows the frisbee to be lightweight and easy to throw, while still providing the necessary stability and consistency in flight.

Overall, polycarbonate is a versatile and reliable material that is well-suited to the manufacturing of frisbees. Its combination of strength, durability, resistance to moisture, and lightweight nature make it an ideal choice for frisbee manufacturers, ensuring that players can enjoy a high-quality and enjoyable experience when playing with a polycarbonate frisbee.

Aluminum

Aluminum is one of the most commonly used materials in the production of Frisbees. It is a lightweight and durable metal that provides a perfect balance between weight and strength. The aluminum used to make Frisbees is typically an alloy, which is a combination of aluminum and other metals such as magnesium or manganese.

The aluminum alloy used in Frisbee production is usually in the form of a disc, which is cut to the desired size and shape. The disc is then annealed, a process in which the aluminum is heated and then cooled slowly to soften it and make it more pliable. This allows the disc to be molded into the desired shape and thickness.

The annealing process also helps to remove any impurities in the aluminum, ensuring that the final product is strong and free from defects. Once the disc has been molded, it is then cut to the appropriate size and shape for the specific Frisbee design.

The aluminum used in Frisbee production is also treated with a protective coating to prevent corrosion and improve its durability. This coating is typically a clear, water-based polyurethane that is applied to the surface of the disc.

Overall, aluminum is an excellent material for making Frisbees due to its lightweight, durability, and strength. Its use in Frisbee production allows for a high-quality product that is both reliable and long-lasting.

Acrylic

Acrylic is a type of plastic that is commonly used in the manufacturing of frisbees. It is a versatile material that is known for its durability, strength, and resistance to wear and tear. The use of acrylic in frisbee production allows for the creation of a disc that is lightweight yet sturdy enough to withstand the rigors of outdoor play.

One of the main advantages of using acrylic in the production of frisbees is its ability to maintain its shape and integrity even when subjected to extreme temperatures. This means that frisbees made from acrylic can be used in a variety of weather conditions, making them a popular choice for outdoor activities.

Another benefit of using acrylic in frisbee production is its resistance to UV rays. This means that frisbees made from acrylic will not degrade or become brittle over time, even when exposed to prolonged sunlight. This helps to ensure that the frisbee remains in good condition for a longer period of time, providing hours of fun and entertainment.

In addition to its durability and resistance to wear and tear, acrylic is also a cost-effective material for frisbee production. It is relatively inexpensive to produce and can be easily molded into a variety of shapes and sizes, making it a popular choice for manufacturers.

Overall, the use of acrylic in the production of frisbees provides a number of benefits, including durability, resistance to wear and tear, resistance to UV rays, and cost-effectiveness. These qualities make acrylic an ideal material for creating high-quality frisbees that can withstand the demands of outdoor play.

The Advantages and Disadvantages of Each Material

Polypropylene is a type of plastic that is commonly used to make Frisbees. It is a strong and durable material that can withstand the impact of being thrown and caught. It is also lightweight, which makes it easy to throw and catch.

One of the main advantages of polypropylene is that it is resistant to most chemicals and does not degrade over time. This means that a Frisbee made from polypropylene will last for a long time and can be used repeatedly without breaking or becoming damaged.

However, one disadvantage of polypropylene is that it can become brittle in cold temperatures. This means that a Frisbee made from this material may become more prone to cracking or breaking if it is used in cold weather.

Another potential disadvantage of polypropylene is that it can release small amounts of gas when it is heated. This can cause the Frisbee to expand and become less stable in flight. However, this is usually not a major concern as the amount of gas released is usually very small.

Overall, polypropylene is a popular choice for making Frisbees due to its strength, durability, and resistance to chemicals. However, it may not be the best choice for players who frequently use their Frisbees in cold weather or plan to heat them up.

Polycarbonate is a thermoplastic polymer that is widely used in the manufacturing of Frisbees due to its unique properties. It is a strong and durable material that is capable of withstanding the rigors of high-speed flight and impact with various surfaces. One of the key advantages of polycarbonate is its high impact resistance, which allows it to withstand the force of collisions without breaking or shattering. Additionally, polycarbonate is also lightweight, which makes it an ideal material for use in flying discs.

Another advantage of polycarbonate is its excellent optical properties. It is transparent and has a high refractive index, which makes it suitable for use in optical applications. This property also allows for the creation of transparent Frisbees, which can be used for various purposes such as training and demonstrations.

However, there are also some disadvantages to using polycarbonate in the manufacturing of Frisbees. One of the main drawbacks is its high cost compared to other materials. Additionally, polycarbonate can also be prone to yellowing over time, which can affect its aesthetic appeal.

Despite these limitations, polycarbonate remains a popular choice for Frisbee manufacturers due to its combination of strength, durability, and optical properties. Its ability to withstand impact and its lightweight nature make it an ideal material for use in flying discs, while its transparency allows for a range of creative applications.

Aluminum is a popular choice for making frisbees due to its lightweight and durable properties. It is a metal that is easily molded into a variety of shapes and sizes, making it an ideal material for manufacturing frisbees.

One of the main advantages of aluminum is its lightweight nature. This makes it easy to throw and catch, and it also reduces the risk of injury during play. Additionally, aluminum is a strong and durable material that can withstand the wear and tear of regular use.

However, there are also some disadvantages to using aluminum for frisbees. One of the main drawbacks is that it can be prone to denting and scratching, which can affect its flight characteristics. Additionally, aluminum can be a relatively expensive material to use, which may make it less accessible to some consumers.

Despite these drawbacks, aluminum remains a popular choice for frisbee manufacturers due to its combination of lightweight, durability, and moldability. Whether you’re a casual player or a professional athlete, an aluminum frisbee can provide a reliable and enjoyable experience on the field.

Acrylic is a type of plastic that is commonly used in the manufacturing of frisbees. It is known for its durability and resistance to wear and tear, making it a popular choice for sports equipment. One of the main advantages of acrylic is that it is lightweight, which makes it easy to throw and catch. Additionally, it is relatively inexpensive compared to other materials, such as metal or glass.

However, there are also some disadvantages to using acrylic in the manufacturing of frisbees. One of the main concerns is that it can crack or break if it is dropped or hit against a hard surface. This can make it less suitable for rough play or heavy use. Additionally, acrylic can become brittle over time, especially if it is exposed to cold temperatures or direct sunlight. This can cause it to lose its flexibility and become more prone to breaking.

Overall, acrylic is a popular choice for frisbees due to its lightweight and affordable nature. However, it may not be the best option for those who need a frisbee that can withstand rough play or heavy use.

Choosing the Right Material for Your Frisbee

Factors to Consider

When it comes to choosing the right material for your frisbee, there are several factors to consider. These include:

- Durability: The material should be able to withstand the wear and tear of regular use, as well as the impact of being thrown and caught.

- Weight: The weight of the frisbee can affect its flight characteristics, so it’s important to choose a material that provides the right balance of weight and durability.

- Grip: The material should provide a good grip, so that the frisbee can be easily thrown and caught.

- Cost: Different materials have different price points, so it’s important to consider your budget when choosing a material for your frisbee.

- Availability: Some materials may be more difficult to find or require special ordering, so it’s important to consider availability when making your choice.

By taking these factors into account, you can choose the right material for your frisbee and ensure that it meets your needs and preferences.

Recommendations

When it comes to choosing the right material for your frisbee, there are a few things to consider. First, you’ll want to think about the type of frisbee you want to make. If you’re making a traditional plastic frisbee, you’ll want to use a material that is durable and can withstand a lot of wear and tear. On the other hand, if you’re making a custom frisbee with a unique design or for a specific purpose, you may want to consider using a different type of material.

One of the most popular materials for making frisbees is polypropylene, which is a type of plastic that is known for its strength and durability. This material is often used to make traditional frisbees because it can withstand a lot of use and abuse without breaking or cracking.

Another option for making a frisbee is to use a material called acrylic. This material is also very strong and durable, and it is often used to make custom frisbees because it can be easily molded into different shapes and designs. Acrylic is also a good choice if you’re looking for a material that is more eco-friendly than traditional plastic.

Ultimately, the choice of material will depend on your specific needs and preferences. If you’re looking for a traditional frisbee that can withstand a lot of use, polypropylene may be the best choice. If you’re looking to make a custom frisbee with a unique design, acrylic may be the way to go.

Maintaining Your Frisbee

Cleaning and Maintenance Tips

To keep your frisbee in good condition and ensure it continues to fly straight and true, regular cleaning and maintenance is essential. Here are some tips for keeping your frisbee in top shape:

- Clean the disc after each use: Dirt, dust, and debris can accumulate on the surface of the disc, affecting its flight. Use a soft, dry cloth to wipe away any dirt or debris. If the disc is particularly dirty, you can use a mild detergent and water solution to clean it. Be sure to rinse thoroughly and dry the disc before use.

- Inspect the disc for damage: Before each use, inspect your frisbee for any signs of damage, such as cracks, cuts, or tears. If you notice any damage, stop using the disc immediately and replace it.

- Store the disc in a safe place: When not in use, store your frisbee in a safe place where it will not be exposed to extreme temperatures, moisture, or direct sunlight. A soft, padded case or a disc sleeve can help protect the disc from scratches and other damage.

- Avoid exposing the disc to extreme temperatures: Extreme temperatures can cause the plastic to become brittle or warped, affecting the disc’s flight. Avoid exposing the disc to temperatures below freezing or above 120 degrees Fahrenheit.

- Replace the disc regularly: Over time, even with proper care and maintenance, frisbees can become worn or damaged. Replace your disc regularly to ensure it continues to fly straight and true.

By following these cleaning and maintenance tips, you can keep your frisbee in top condition and enjoy many hours of fun and exciting play.

Storing Your Frisbee

Proper storage is essential to ensure the longevity and durability of your frisbee. Follow these guidelines to store your frisbee safely:

- Avoid direct sunlight: Direct sunlight can cause the materials to degrade and discolor over time. Store your frisbee in a cool, dry place with minimal exposure to sunlight.

- Use a protective case: Invest in a protective case or a soft, padded bag to store your frisbee when not in use. This will prevent scratches, dents, and other types of damage that can occur due to rough handling or storage.

- Stack carefully: If you need to store multiple frisbees together, make sure to stack them carefully to avoid any damage to the rim or the edge of the disc. Place a soft barrier, such as a towel or cloth, between each frisbee to prevent scratches or other types of damage.

- Keep it clean: Wipe down your frisbee with a soft, dry cloth after each use to remove any dirt, dust, or debris that may have accumulated on its surface. This will help prevent the growth of mold or mildew and ensure that your frisbee stays in good condition for a longer period of time.

- Inspect regularly: Regularly inspect your frisbee for any signs of wear and tear, such as tears, cracks, or other types of damage. If you notice any issues, it’s important to address them promptly to prevent further damage and ensure that your frisbee remains safe and functional for use.

Recap of Key Points

- Keep your frisbee clean and dry to prevent damage to the plastic and the disc’s performance.

- Use a soft, dry cloth to wipe away any dirt or debris.

- Avoid exposing your frisbee to extreme temperatures, as this can cause warping or cracking.

- Store your frisbee in a safe place when not in use, away from sharp objects or rough surfaces that can scratch or damage the disc.

- Check for any signs of wear and tear, such as tears or cracks, and replace your frisbee if necessary to ensure it continues to fly straight and true.

Final Thoughts on Frisbee Materials

In conclusion, the materials used to make a frisbee play a crucial role in its performance and durability. The plastic used in the disc’s construction, whether it’s polypropylene or polycarbonate, is crucial in determining the disc’s stability and glide. The weight of the disc, determined by the thickness of the plastic, also affects its performance. Additionally, the rim and the disc’s overall design also impact its flight characteristics.

When it comes to maintaining your frisbee, it’s important to keep it clean and free from dirt and debris. This can be done by washing it with soap and water or using a specialized cleaning solution. It’s also important to avoid exposing your frisbee to extreme temperatures, as this can cause it to warp or become brittle.

Investing in a high-quality frisbee made from durable materials can save you money in the long run by reducing the need for frequent replacements. It’s also important to consider the materials used in the rim and the disc’s design when purchasing a frisbee, as these can impact its performance and longevity.

Overall, the materials used to make a frisbee are an essential factor in its performance and durability. By understanding the different types of plastic used in frisbee construction, the impact of weight and rim design, and how to properly maintain your frisbee, you can ensure that your disc will provide you with many hours of fun and enjoyment.

FAQs

1. What is a Frisbee made of?

A Frisbee is primarily made of a thin, solid plastic material called polyethylene. The plastic is molded into a disc shape with a rim and a center hole. Some Frisbees also have a printed design on one or both sides.

2. What type of plastic is used to make a Frisbee?

A Frisbee is typically made of high-density polyethylene (HDPE), which is a strong and durable plastic that can withstand the impact of being thrown and caught. HDPE is also recyclable, making it an environmentally friendly choice for a sport disc.

3. Are Frisbees made of different materials for different sports?

Yes, there are different types of Frisbees designed for different sports. For example, Ultimate Frisbee is played with a 175g plastic disc, while the Classic Frisbee is lighter at 160g. The material used to make the Frisbee remains the same, but the weight and dimensions may vary depending on the sport.

4. Are Frisbees made of metal or other materials?

No, Frisbees are not made of metal or any other materials besides plastic. The plastic used to make a Frisbee is specifically chosen for its durability and ability to withstand the impact of being thrown and caught.

5. Can Frisbees be made from other materials?

It is possible to make Frisbees from other materials, such as aluminum or other metals, but these materials would not be as durable or as lightweight as plastic. Additionally, aluminum Frisbees would be much more expensive to produce than plastic Frisbees.

6. Are Frisbees safe to use?

Yes, Frisbees are safe to use when they are made of high-quality materials and are used properly. However, as with any sport, there is always a risk of injury, so it is important to follow proper safety guidelines and techniques when playing with a Frisbee.